How Lancashire's salt mining industry began

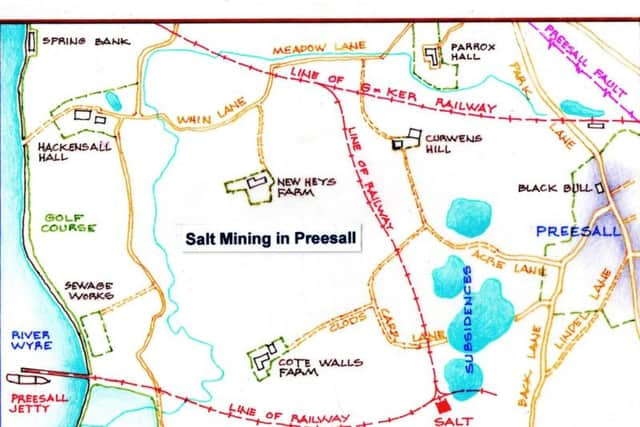

In 1872 the village of Preesall was still a quiet rural backwater, difficult of access and undisturbed since the Civil War, not yet reached by the construction of a railway from Garstang, the nearest market town.

A village pub, the Black Bull, presided over by landlord John Parkinson, described as ‘the finest sportsman one could hope to meet on a country walk,’ was patronised by farmers and local tradesmen and frequented by the local squire, Daniel Hope Elletson of Parrox Hall.

Advertisement

Hide AdAdvertisement

Hide AdAn idyllic scene, but all this was to change. That year a syndicate of men from Barrow-in-Furness arrived and, lodging at the Black Bull, began putting down boreholes in a search for iron ore. There was no iron ore to be found, but in a borehole about half a mile south west of Preesall village they discovered a bed of rock salt approximately 400 feet thick 300 feet below ground. They took a sample back to the Black Bull where the landlord’s daughter, 17-year-old Dorothy Parkinson, dissolved, filtered and boiled it to produce the very first sample of Preesall salt.

It seems they had intended to put down 20 bore holes but, apparently discouraged by their failure to find iron ore, only put down three before leaving. Further action was therefore left open to others and several borings were made during the early 1870s revealing more deposits of salt, a large supply of fresh water and the existence of the Preesall geological fault.

In 1875 the first exploratory shaft was sunk by the Reverend Daniel and his brother-in-law Daniel Hope Elletson, who had no doubt been one of the very first to hear about the new discovery. The 8ft diameter shaft, lined with brickwork, encountered the top of the rock salt at a depth of 309ft and continued down to 525ft without reaching the bottom.

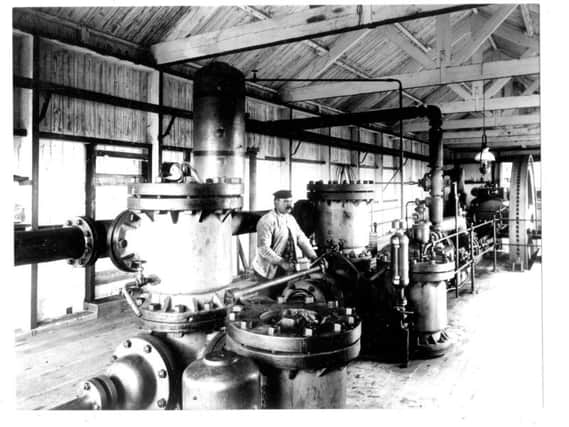

Commercial interests then took over and events took on a momentum of their own. In 1883 the Fleetwood Salt Company was established to exploit the salt field and a further shaft was sunk, revealing a rocksalt bed 340ft thick. Water was allowed to seep into the rock head and the resulting brine was pumped out by a steam driven engine working 24 hours a day. This was the first time, but by no means the last, that the old rural idyll was to be disturbed.

Advertisement

Hide AdAdvertisement

Hide Ad

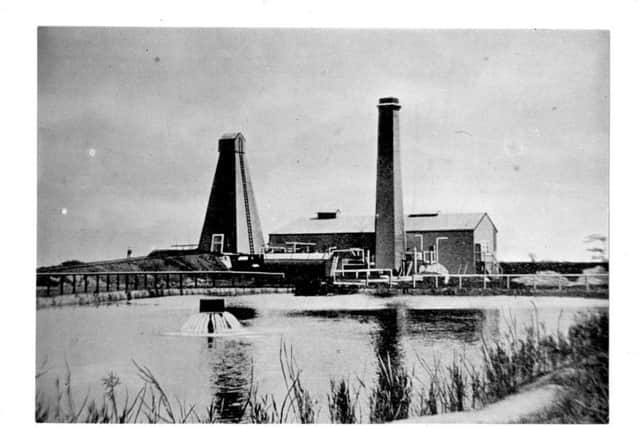

In 1889 the company purchased 22 acres of the Fleetwood saltmarsh at Burn Naze and reclaimed it for the construction of salt works. Railway sidings with a connection to Wyre dock were installed and rates for haulage agreed with the Preston and Wyre Railway Company.

Mineral rights over 11,000 acres of land in Preesall, with all necessary wayleaves for pipelines etc., were obtained; drilling of further boreholes was commenced, a brine reservoir was constructed, and pipelines laid to, and across the Wyre to Burn Naze. The scene was set; in 1890 the Fleetwood Salt Company was taken over by the United Alkali Company, a national organisation, and the level of activity began to gather pace.

During the following year the Fleetwood Chronicle reported many further boreholes were drilled, workers’ cottages were constructed, miners began forming a tunnel from the old shaft to enable the quarrying of rock salt, and the works at Burn Naze were expanded to include ammonia soda works and new salt works in addition to the existing 13 pans in use and seven under construction.

By the end of 1891 a reliable pipeline was in operation under the Wyre, salt was being exported from Fleetwood at the rate of six ships a month and the company had decided to exploit the rocksalt deposits in three ways – ammonia soda works, salt works, and also rocksalt mining.

Advertisement

Hide AdAdvertisement

Hide Ad

However, the first indications of future problems had already arisen when, in January 1890, it was discovered the rocksalt had dissolved away behind the brickwork of No. 2 shaft leaving it without support. Repairs were carried out, but much more seriously in August 1891 a subsidence over 40 feet deep and more than one third of an acre in extent, known as Acre Pit, opened up around No.23 borehole.

The Fleetwood Chronicle casually noted such subsidences were very common in salt districts and that ‘’no doubt the good people of Preesall will in time come to regard the collapse of a field or two with supreme indifference.’’ These were prophetic words.

Ignoring this minor incident by 1893 the company had built an ammonia soda works on a new 42 acre site, drilled more boreholes and built a pumping station to force brine to the surface under pressure. The water was supplied by the new Parrox wells, which commenced in 1894, producing 45,000 gallons per hour.

Rocksalt mining also commenced in 1893 via two new 450ft deep shafts, one of which was later extended to 900ft to form the lower mine. The bottoms of the shafts were blasted out until a cavern was formed, following which salt was obtained by blasting, using black gunpowder bobbins stemmed in and fused with long wheatstraws filled with gunpowder and tipped with a piece of candlewick.

Advertisement

Hide AdAdvertisement

Hide Ad

Eventually the caverns were between 16ft and 40ft high with pillars of salt 60 feet square left every 105ft as supports. The mines were lit by electricity except near the rock face where blasting was being carried out, where candles stuck in moist clay were used. Winches powered by compressed air pulled trains of tubs containing rocksalt to the shafts, where they were hoisted to the surface, also serving as lifts for the miners.

By 1906 the mine was producing 140,000 tons of rocksalt per annum and steamers up to 1,600 tons were being loaded at the new Preesall jetty on the Wyre, served by railway trucks on a rail line direct from the mouth of the mine.

As demand for skilled labour rose, many families such as Maddock, Rowe, Davies, Fairhurst, Phillips and Daniels moved to Preesall from the salt field of Northwich in Cheshire and the population consequently doubled between 1891 and 1911,rising from 893 in 1891 to 1,412 in 1901 and 1,718 in 1911. Company houses were built and the total number of inhabited houses rose from 185 in 1891 to 312 in 1903.

Preesall began to look different and the old rural idyll receded as strange new structures appeared in the countryside, the state of the roads deteriorated, the lanes filled with workmen going to and from the mines, pumping stations and wells, and the sound of 24 hour pumping reverberated across the fields.

Advertisement

Hide AdAdvertisement

Hide AdPreesall hit the national headlines when ‘The Times’ reported in November 1906: “A descent into the Preesall pit is an experience of unusual interest. Though the mining operations have only been conducted for a dozen years, the weird, lofty, cavernous vaults formed by the excavation of over 1m tons of salt are sufficiently impressive, when illuminated as they are by electricity, to bewilder the spectator who visits them for the first time.’’

The article continued with a description of the company operations and the statement, “Preesall salt has established itself a very high reputation both in the Australian and South American markets…’’

Future prosperity seemed assured, but all was not well below ground. Since the formation of Acre Pit gradual subsidence had continued around No. 21 borehole until by 1911 a five acre ‘flash’ had formed, used by the company as a supply of water without any apparent concern.

However, in November 1901 a serious subsidence had also occurred around No. 28 borehole. It was reported a large plot of land had collapsed entirely, expanding within a month to a hole 100ft deep by 135ft in diameter, endangering the works and the chimney. The subsidence continued to expand until eventually stabilising by 1911 into a roughly circular hole 300ft in diameter.

Advertisement

Hide AdAdvertisement

Hide AdDespite such clear warnings mining and brine extraction continued apace and in 1912 a mile long branch line was opened from the Garstang & Knott End Railway to the Preesall salt works, providing a direct link to the national rail network.

Two special trains ran every day from the works to the G&KER line and in 1918 over 30,000 tons of salt left the works by rail and almost 8,000 tons of fuel and materials were brought in. The salt and ammonia soda works over the river were now requiring more brine, necessitating the sinking of yet more wells in Over Wyre and the erection of water softening plant in Preesall to modify the hardness of the water. It was as if no problems had ever been encountered, but the very worst was yet to come.

* With thanks to Rosemary Hogarth for permission to use her very extensive and detailed work on the Preesall salt industry without which this account would not have been possible.